SterilAir leads the way in the successful development and manufacturing of UVC disinfection devices and components. With over 70 years of developing environmentally and health friendly UVC technology for the disinfection of surface, air and water, sterilAir provides a wide range of systems for various applications within the food processing, medical, air conditioning, ventilation, industrial & commercial buildings, warehouse storage, packaging, laboratories, water treatment, and livestock breeding industries.

SterilAir leads the way in the successful development and manufacturing of UVC disinfection devices and components. With over 70 years of developing environmentally and health friendly UVC technology for the disinfection of surface, air and water, sterilAir provides a wide range of systems for various applications within the food processing, medical, air conditioning, ventilation, industrial & commercial buildings, warehouse storage, packaging, laboratories, water treatment, and livestock breeding industries.

SterilAir has proven results of the highest standards in disinfection, helping companies maximize profits and increase hygiene by reducing downtime required to sanitize food production surfaces, improving food and air quality from reduced contamination.

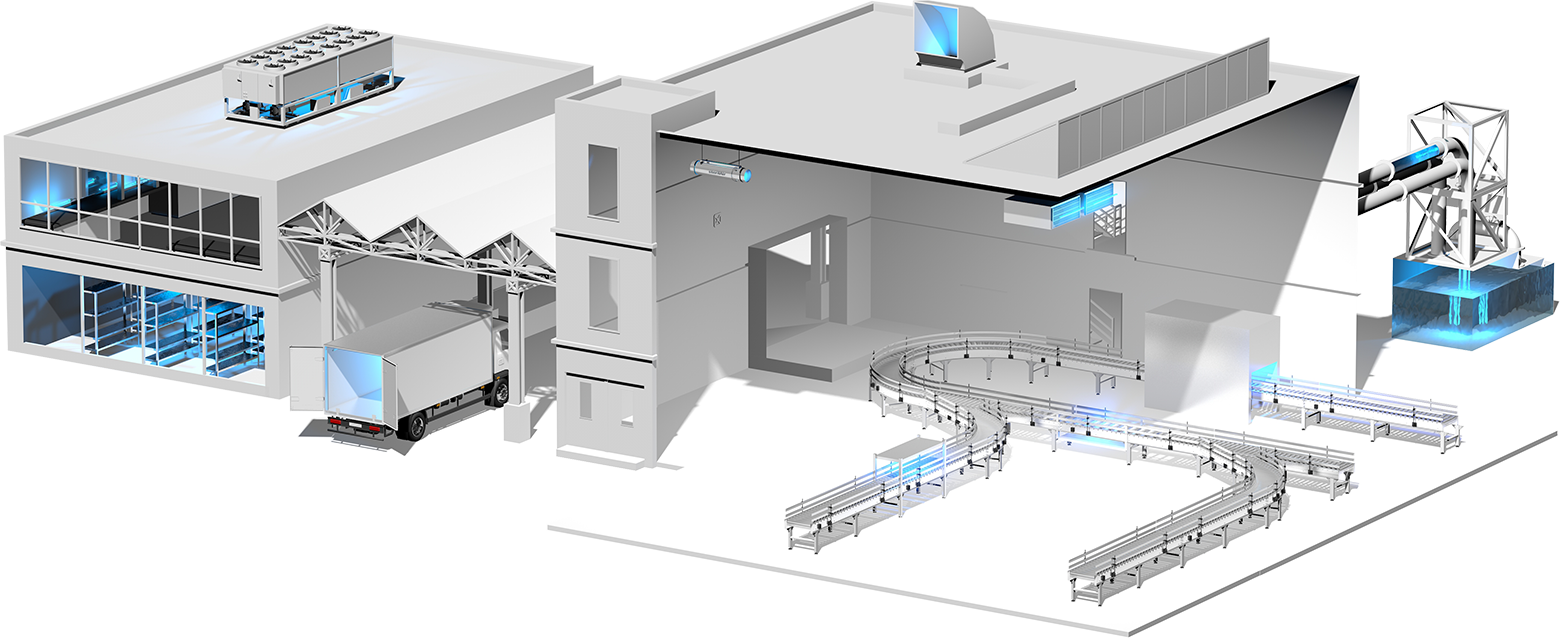

Where are our products used?

Click on the BLUE HIGHLIGHTED SPOTS on the image to see more.

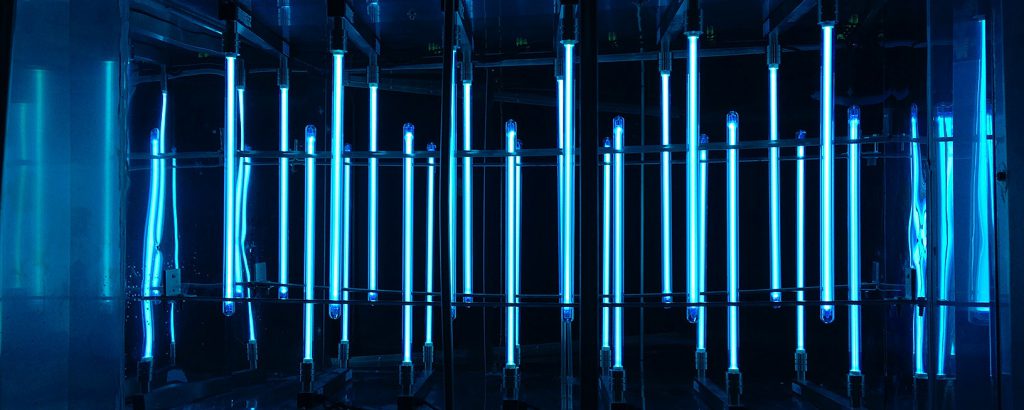

UVC Water Series

Versatile Immersion Heater

- UV-transparent, aqueous media can be simply and very effectively sterilised with sterilAir submersible lamps.

- The simple design allows uncomplicated retrofitting into existing systems.

- The carefully processed stainless steel construction and multiple sealing rings in the sturdy screw connection guarantee maximum operational safety.

UVC Surface Series

Equipment for Surface Disinfection

- Superstructure systems are the classic UV devices for disinfecting surfaces.

- The UV-C radiation is clustered using special reflectors and focused on the surface to be treated.

- Due to the particularly high radiation intensity, micro-organisms are inactivated in no time at all.

- The low surface temperature of max. 41°C allows safe exposure to heat-sensitive materials.

UVC Water Series

Versatile Immersion Heater

- UV-transparent, aqueous media can be simply and very effectively sterilised with sterilAir submersible lamps.

- The simple design allows uncomplicated retrofitting into existing systems.

- The carefully processed stainless steel construction and multiple sealing rings in the sturdy screw connection guarantee maximum operational safety.

UVC Air Series

Built-in Modules for HVAC Systems

- Easy integration into existing ventilation technology systems and components.

- Nearly air-resistant, highly effective bactericidal disinfection lock.

- Using complex software models, the number of required UV units, taking into account all relevant parameters, is calculated scientifically.

- sterilAir special tubes allow smooth operation even under the toughest conditions.

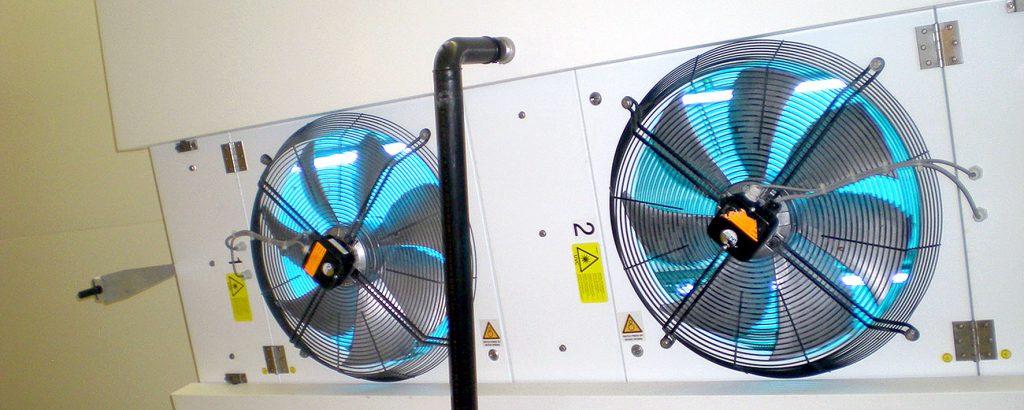

UVC Air Series

Hygiene Kit for Air Coolers

In normal operation, germs attach themselves to the cooling fins of the air coolers as biofilm. Defrost cycles provoke growth and spores are carried into the room via the air ejection.

- The sterilAir E series effectively suppresses the formation of biofilms on the cooling lamellae.

- A consistently low germ load of the room air guarantees longer shelf life of products in the food industry.

- The sterilAir disinfection system outperforms conventional air cooler hygiene concepts in terms of efficiency and economy.

UVC Air Series

Photoreactors for water disinfection

- sterilAir AQD flow units are an effective measure for the disinfection of domestic and industrial water

- The product range includes low-cost PVC variants or high-quality systems made of stainless steel

- Due to a large number of sizes and performance classes, configurations for a wide variety of requirements of 0.8 m³/h - 10 m³/h are possible.

UVC Air Series

UV disinfection in the recirculation method

- sterilAir recirculating air sterilisation systems are used for continuous air disinfection in rooms with low convection or in those in which a direct emission must be avoided

- sterilAir offers various air circulation sterilisation systems for an application range up to 700 m³/ h

- All systems are easy to install and maintain

- Inactivation of > 90% mould spores in a single passage

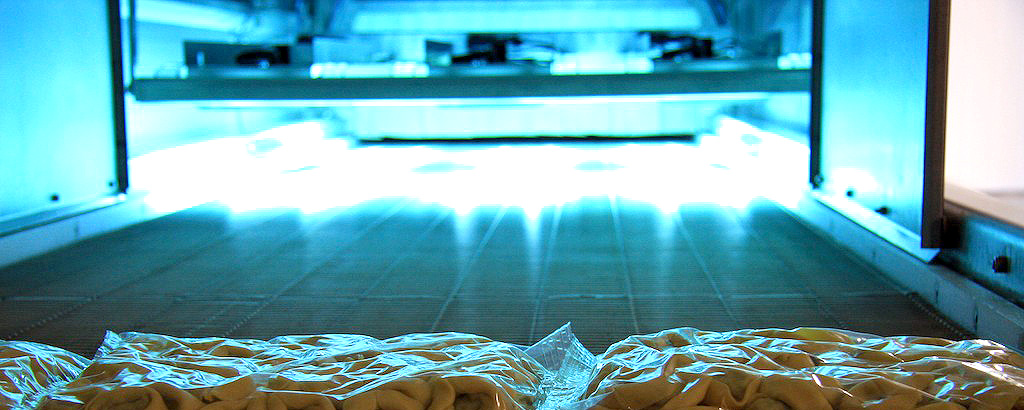

UVC Surface Series

Conveyor Belt Disinfection System

- With the design of devices for sub-assembly, sterilAir has been able to establish a standard that is now widely used

- This type of installation can effectively prevent contact and smear infections from meat and fresh products

- Despite multiple shift operation, belts and containers remain microbiologically safe during ongoing production

- Work processes don't have to be interrupted

UVC Surface Series

Components for individual installation

- sterilAir UV units are market-proven industrial components that meet the high demands of professional applications

- Long service lives of the UV tubes, exemplary low energy consumption and a low surface temperature also allow for the use of heat-sensitive materials

- Thanks to our laboratory, elaborate measuring equipment and our construction department staffed with qualified specialists, we are in a position to implement special customer requirements even while observing the highest quality requirements

UVC Surface Series

Systems for individual needs

Whether it’s a laboratory for microbiology, a clinic or a cleanroom in the food industry - the application sectors are as diverse as our products and components.

- sterilAir systems effectively and demonstrably deactivate bacteria, viruses and spores

- Extremely short decontamination times for maximum flexibility

- All systems are easy to install and maintain

UVC Air Series

Sterilisation device for ceiling assembly

- sterilAir UV sterilisation devices help protect items stored in warehouses and cold-storage rooms

- The system can also be fitted with a detachable safety screen or an automatic output regulator, if required

- For rooms with minimal footfall and UVC resistant materials

UVC Air Series

Direct spotlight for ceiling mounting

- sterilAir ceiling-mounted UV sterilisation units for use in production rooms, laboratories or transport facilities

- Nocturnal or timed surface disinfection with room air disinfection

- Functional optimisation for system requirements through components such as impact protection, grid attachments, screens and reflectors

Air Disinfection

The conventional ventilation and air circulation systems are not effective in preventing exposure to bacteria, viruses and microorganisms in enclosed areas. In food production air circulation systems, the spread of microorganisms leads to mould or reduced product quality.

With comparatively low investment, reap the benefits of the sterilAir UVC disinfection of reduced infection from air-borne germs and improved food quality in food processing areas.

There are different types of sterilAir air disinfection installations to suit the room space, purpose and amount of food traffic:

- Air Recirculation Units – suitable for industrial and commercial areas such as food production rooms and laboratories, and are easy to install and maintained.

- Wall Mounted Systems – a great for regular room space with normal foot traffic.

- Ceiling Mounted Systems – generally used in production areas or laboratories where intensive air disinfection is vital.

- HVAC Systems – which can be retrofitted in existing air conditioning units.

| ESD-EX - Installation Kit for Air Ducts

|

| UVR-4K Industrial UV Air Recirculation Unit

|

| D-Series Disinfection system for wall and ceiling installation

|

Surface Disinfection

Sterile packages and transportation belts are one of the most important prerequisites in the food industry to maintain hygiene and quality of dairy products, meat and fresh produce. With UVC radiation, safe and reliable disinfection is guaranteed - without unfavourable effects of heat or unwanted additives, without any residue and within the shortest space of time.

Conveyor Belt Disinfection

In conveyor belt disinfection, sterilAir established a widespread standard in the design of systems for substructure installation. This installation type effectively prevents contact contamination of meat and fresh produce.

Belts and containers remain free from contamination even under continuous shifts, reducing downtime from shutdowns to sanitize food production surfaces. More production time means more yields!

Systems for Surface Disinfection

Superstructure systems are the traditional UV systems for surface disinfection. The UVC radiation is bundled with the assistance of special reflectors and then focused on the surface to be disinfected. The high radiation intensity incapacitates microorganisms in the shortest time possible. The very low surface temperature of the sterilAir appliances (~ 41 °C) also allows safe disinfection for materials that are sensitive to heat.

| E-Series: ET Surface disinfection

|

| T2018 Surface disinfection system

|

Water Disinfection

UVC treatment of water does not cause any of undesirable side effects that chemical disinfectants do – corrosion, foaming and odour formation, to name a few. It is a purely physical process that does not generate any undesirable side effects or residues. At the same time, the cost efficiency of this disinfection method is impressive.

| E-series: EQ Immersed system This combination has been specially designed for the submerged use in water. The back of the lamp holder does not have a plug connection for the supply cable, but the cable is cast in a fixed manner. Areas of application:

|

| AQD-ST Stainless steel flow-through systems sterilAir AQD-ST series of stainless steel flow-through equipment offer compact small systems with annular geometry up to six-flame UV-C systems with negative irradiation geometry. All relevant parts of sterilAir AQD-ST consist of a particularly high-grade stainless steel (WN 1.4404/ 316L), which have been additionally double pickled and passivated to increase the corrosion resistance.

|

||

AQD-ST 1 | AQD-ST 3 | AQD-ST 6 |

|

|   |   |

|

To view videos related to this product, please click here or go to the VIDEOS navigation link at the top of this page.

Service & Delivery

IBEX prides itself on its customer service. With the unpredictable nature of the industry, IBEX’s policy is to ensure that we can supply the right product at the right price immediately. We have invested heavily to ensure that we are able to deliver the product to you when you need it the most.

Combined with our own manufactured products, our agency lines ensure we are a one stop shop for our customers’ production needs.

Brands that IBEX distributes in New Zealand, include:

Contact IBEX to find out how we can work together, to meet your specific needs.