![]() IBEX teamed up with Munkfors over 25 years ago to bring you the best blading available on the market today. Munkfors has been leading the blading business since 1948 and has developed their unique patented profile-grinding method to produces blades which:

IBEX teamed up with Munkfors over 25 years ago to bring you the best blading available on the market today. Munkfors has been leading the blading business since 1948 and has developed their unique patented profile-grinding method to produces blades which:

-

- are sharper

- cut cleaner

- produce less material waste

- last longer

- cause fewer production disruptions

Munkfors bandsaw blades incorporate a unique manufacturing technology to guarantee blade products with high quality and long life.

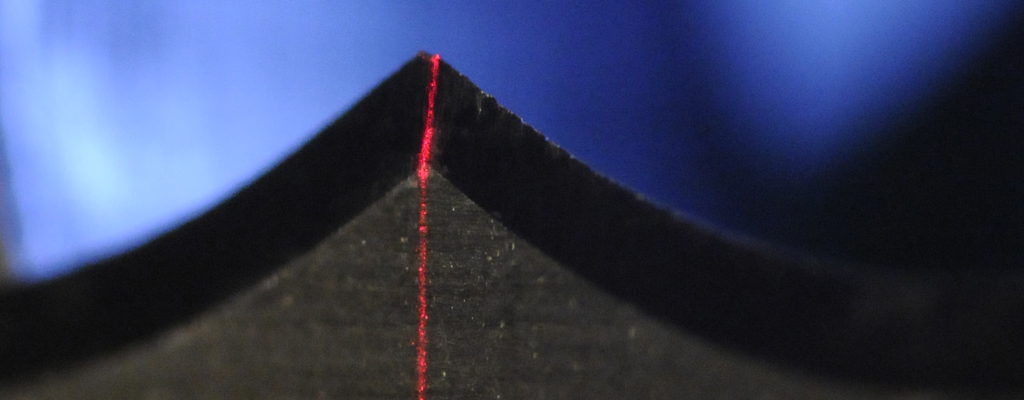

The Munkfors Manufacturing Process

-

- Munkfors select strip steel from the world’s leading steel manufacturers

- From this strip they grind the blades teeth with a patented profile grinding method

- This grinding gives an extremely sharp edge over a traditional punched or mill method

- The quality of strip steel and the patented profile grinding method produce sharper cutting edges and high quality blades tooth after tooth after tooth

Maintaining the Standards

To deliver the best final product we take the Munkfors coil, and carefully cut & weld the product. The coil is cut and tooth matched to ensure the final blade has a continuous teeth numbers through the welded area. The blade is then welded and cleaned to give a well-balanced blade to ensure maximum cutting potential, and to produce accurate cutting and better final product appearance.

Right Product for the Job

For every cutting operation, and every bandsaw IBEX can supply the right bandsaw blade for the specific application. Whether it is for chicken, fish, beef or lamb, frozen fresh or chilled, bone in or out. Blades are also available for handsaws and carcass splitting saws.

Interested then please talk with us. IBEX has the blading solution for you.

Specifications

Munkfors have an extensive range of blades, from their standard blades for general processing, through to their minimum set options with reduced sawdust for increased yields. With patented profile grinding techniques Munkfors are able to produce blades which have a smaller set but achieve the same high product feed rates of larger set blades.

Munkfors minimum set blades decrease the sawdust wastage due to their reduced set but still have a higher feed rate due to the sharpness of the blade which results in a longer blade life.

There has long been a compromise for blade manufactures between reducing the set of the blade to decrease sawdust vs. having an increased blade set to improve feed rates; the Munkfors blade incorporates both criteria for maximum efficiency.

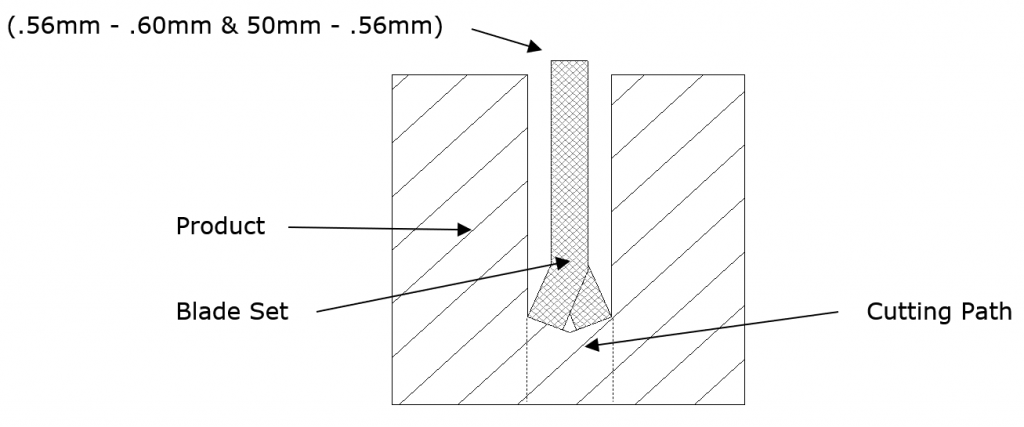

The set on .56mm - .60mm & .50mm - .56mm bandsaw blades creates a slot, or cutting path in the product, this cutting path is wider than the back of the blade and is the factor that determines the saw dust volume that is produced from a bandsaw blade.

Blade Thickness

The Munkfors minimum set blade has a narrower cutting path than the standard blade currently in use, producing a 14% reduction in saw dust over standard set blades, resulting in greater yields and reduced sawdust smear.

Blade Length/Width: | This is dependent on the Bandsaw model and subject to the type of product being processed, and is able to be customised to meet individual requirements. | |||

As a guide: | ||||

Thickness: | .60mm (025) .56mm – .60mm .50mm – .56mm | - Frozen - Fresh - Portion Cutting | ||

Teeth Alternatives: | 3 Teeth per inch 4 Teeth per inch SPS | - Fresh or Frozen - Traditional Fresh - Fresh, Portion Cutting | ||

Tooth Setting: | Standard Set Minimum Set Positive Set | - Fresh or Frozen - Fresh, Frozen, Portion Cutting - Beef Splitting | ||

Bandsaw Blade Options

| Product Code | Description | ||||||

|---|---|---|---|---|---|---|---|

M | 12 | 50 | 4 | XXXX | TPI = Teeth per Inch | ||

| M | Munkfors Blade | ||||||

| 12 | Height of the blade in mm e.g. 12mm High | ||||||

| 50 | Width of the blade specification in mm e.g. 0.50mm wide | ||||||

| 4 | Teeth per inch e.g. 4 TPI | ||||||

| XXXX | Cut length specification as requested by the customer | ||||||

| M12504: 4 TPI | For general cutting on fresh product. | |||||

| M16604: 4 TPI X 16mm | For general cutting on fresh product. | |||||

| M16603: 3 TPI X 16mm | For general cutting on fresh product. | |||||

| M16563M: 3 TPI X 16mm | For reduced saw dust waste. Can be used for fresh cutting as well as for frozen product. Minimum set for reduced sawdust content. | |||||

| M1660S: 3 TPI X 16mm | Used for fresh cutting additional small teeth in gullet assists in clearing sawdust from surface of product. | |||||

| M19563M: 3 TPI X 19mm | For reduced saw dust waste to suit larger saws for primal cutting. Can be used for fresh cutting or frozen product. | |||||

| M1956S or P: | Used for beef splitting operation in the slaughterhouse. | |||||

| M20603 or 4: 3 TPI for frozen cutting or 4 TPI for fresh cutting 20mm wide | Used for primal cutting on large saws. | |||||

Videos

To view videos related to this product, please click here or go to the VIDEOS navigation link at the top of this page.

Service & Delivery

IBEX prides itself on its customer service. With the unpredictable nature of the industry, IBEX’s policy is to ensure that we can supply the right product at the right price immediately. We have invested heavily to ensure that we are able to deliver the product to you when you need it the most.

Combined with our own manufactured products, our agency lines ensure we are a one stop shop for our customers’ production needs.

Brands that IBEX distributes in New Zealand, include:

Contact IBEX to find out how we can work together, to meet your specific needs.